Around 2014, “drones,” quadcopters in particular, were becoming popular.

Commercially-available options were either out of my budget, lacking in features, or had unimpressive specifications. I chose to build my own, and this started a multi-year revision process.

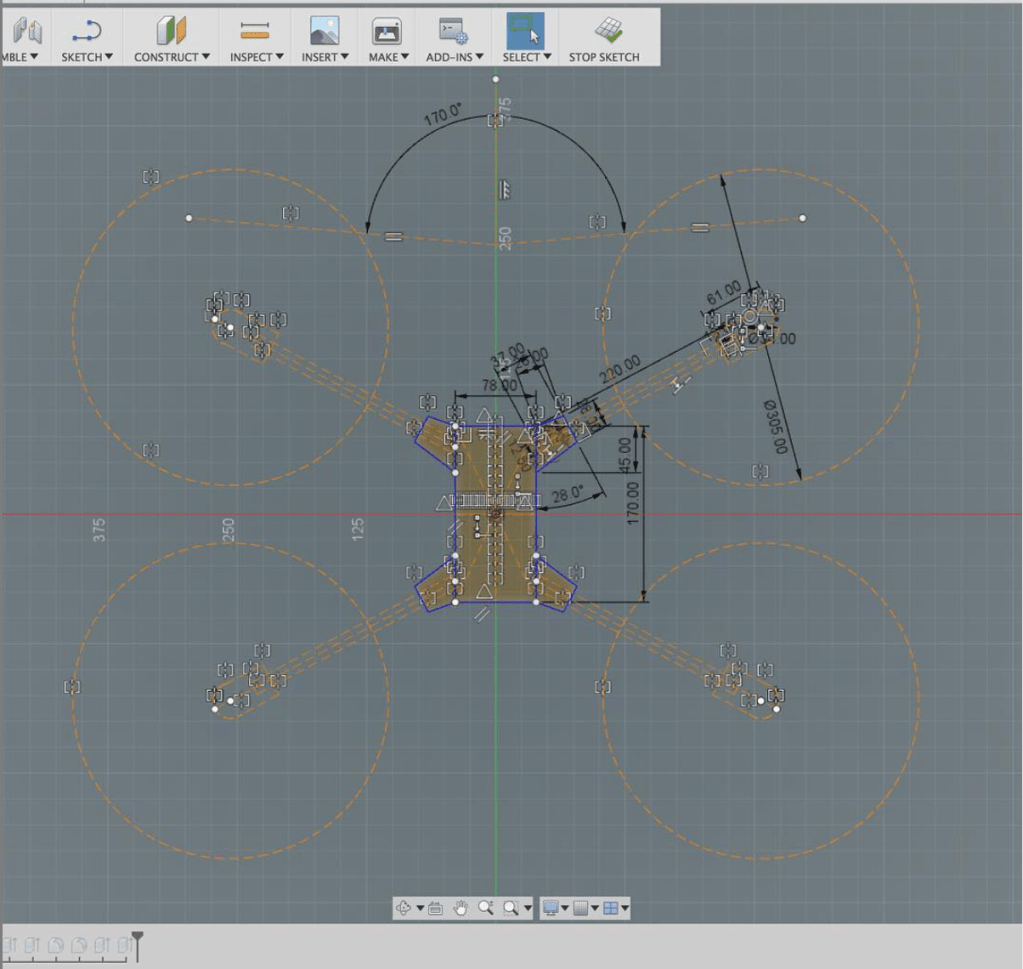

My objectives were to build a drone with first-person live video feedback, an onboard, 2-axis stabilized GoPro for HD video recording, sufficient battery life, and an industrial design philosophy that emphasized ruggedness.

This page details the various revisions I made over time, to achieve those goals.

The drone in the above video is revision 2. It uses 0.070″ thick aluminum top and bottom plates that I machined myself, along with 0.500″ carbon fiber tubes and fiberglass landing rails. Most other parts are off-the-shelf.

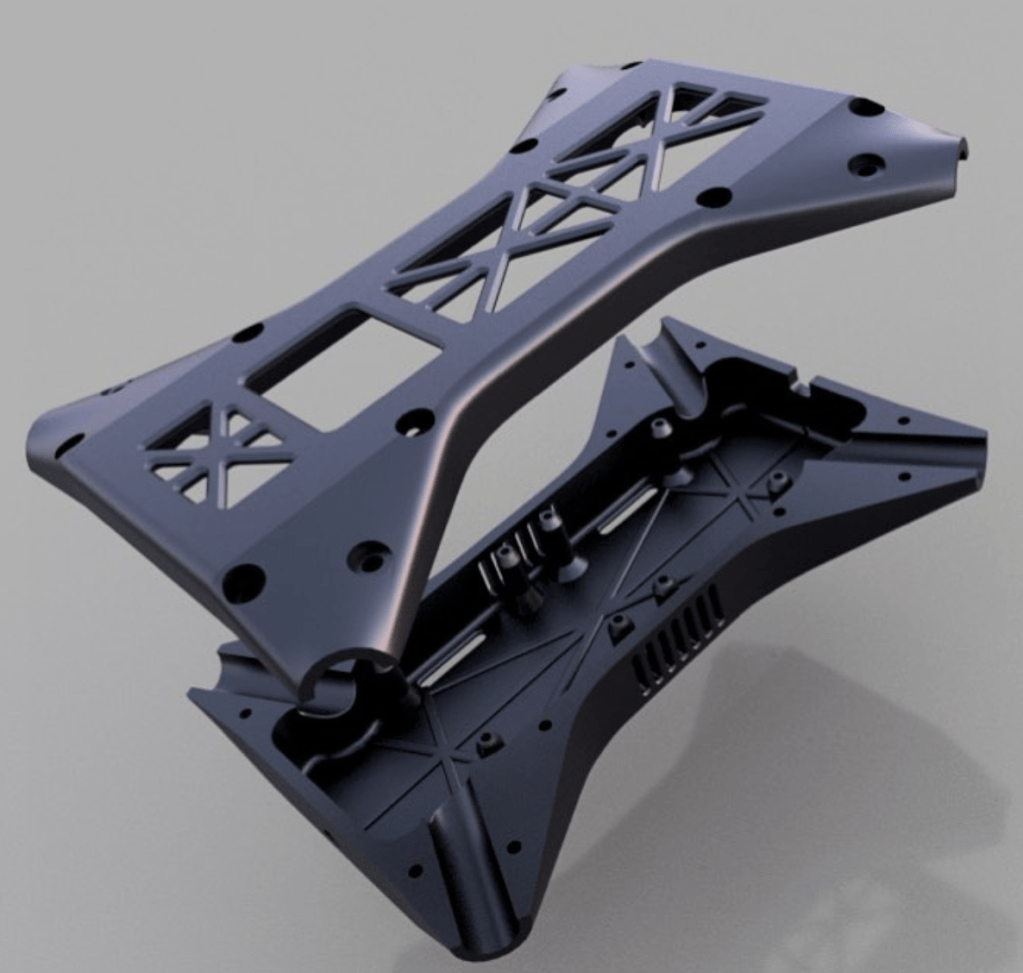

Minor changes occurred over time, before I eventually settled on a printed ABS design to save on weight (to the benefit of flight endurance).

I solvent-welded a battery compartment to the bottom, and it flew well:

Flight of the Clamshell Design:

Not long after the last video, I lost the drone during a crash. The clamshell assembly was too weak. The aerodynamic performance was better than expected; the low MOI (thanks to most of the mass being highly concentrated about the COG) meant that it was very responsive to inputs.

While I still have confidence in the design, I chose to pursue fixed-wing UAV’s after this crash, gutting this drone and utilizing the parts on the next build.